Power+Energy Hydrogen Separators produce ultra-high purity hydrogen from hydrogen rich gas streams for Fuel Cells. Each H2 separator may be custom designed to match the specific conditions of the customer’s application.

Power+Energy manufactures H2 separators ranging in hydrogen output from 0.5 slpm, capable of feeding a 50W fuel cell, up to 1,200 slpm, capable of feeding a 120kW fuel cell.

Our Separator technology is often used to extract the hydrogen from reformate streams generated by steam or auto-thermal reformers.

In other cases P+E Separators extract H2 from a process by-product stream, from bio-gas (digesters, etc.) or from closed-circuit H2 recirculation systems.

Power+Energy manufactures H2 separators ranging in hydrogen output from 0.5 slpm, capable of feeding a 50W fuel cell, up to 1,200 slpm, capable of feeding a 120kW fuel cell.

Our Separator technology is often used to extract the hydrogen from reformate streams generated by steam or auto-thermal reformers.

In other cases P+E Separators extract H2 from a process by-product stream, from bio-gas (digesters, etc.) or from closed-circuit H2 recirculation systems.

Design and Operation

Power+Energy Hydrogen Separators use Micro-Channel Palladium Alloy Membranes to extract hydrogen from the feed stream. For mixed gas streams containing sulfur compounds, a sulfur-tolerant palladium alloy is used. In some applications, customers use a sweep gas, either nitrogen or steam, to boost the hydrogen recovery of the H2 separator.

Power+Energy Hydrogen Separators use Micro-Channel Palladium Alloy Membranes to extract hydrogen from the feed stream. For mixed gas streams containing sulfur compounds, a sulfur-tolerant palladium alloy is used. In some applications, customers use a sweep gas, either nitrogen or steam, to boost the hydrogen recovery of the H2 separator.

H2 Separator Operating Parameters

Basic Terms:

Operating Parameters :

Basic Terms:

- Reformate: Outlet gas mixture from Fuel Reformer

- Raffinate: Waste gas stream out from separator

- Permeate: Ultra-pure hydrogen stream from the separator

Operating Parameters :

- Maximum reformate inlet pressure = 300 psig

- Operating temp range = 300-500°C, recommended temperature = 400°C

- Maximum pressure differential = 180 psi (reformate press. – permeate press.)

- Maximum reverse pressure differential = 10 psi (permeate press. – reformate press.)

- Membranes should not be exposed to H2 when below 300 °C to avoid embrittlement.

- It is recommended that a backpressure regulator is installed in the raffinate line.

- Preheat membranes with steam, hot air or hot inert gas prior to flow of H2 or reformate.

- Purge membranes with steam or inert gas prior to allowing membranes to cool below 300°C.

- It is recommended to monitor the raffinate outlet gas temperature in order to ensure that the membrane temperature remains above 300 C while h2 containing gases are flowing through the separator.

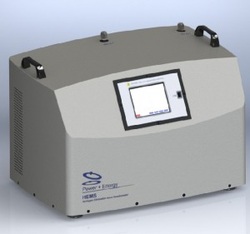

The Power+Energy HEMS™ series of Hydrogen Purity Analyzers are full spectrum instruments with limits of detection per impurity of < 1 ppt*. The analyzer is self-calibrating and, with a short analytical cycle time, can be used as an on-line impurity monitor. The compact package and automatic operation make it easy to use for quick sample verification at multiple points.

The HEMS (hydrogen elimination mass spectrometer) analyzer uses P+E’s patented palladium diffusion technology combined with advanced quadrupole mass spectrometry to achieve parts-per-trillion resolution.

Compared to other analyzers, HEMS offers detection of the broadest range of impurities in a compact enclosure with automated operation at an affordable cost.

Product Specifications

The HEMS (hydrogen elimination mass spectrometer) analyzer uses P+E’s patented palladium diffusion technology combined with advanced quadrupole mass spectrometry to achieve parts-per-trillion resolution.

Compared to other analyzers, HEMS offers detection of the broadest range of impurities in a compact enclosure with automated operation at an affordable cost.

Product Specifications