MVA - MultiVariantAnalysis

실시간 IoT 상태와 데이터를 얻고 관리합니다.

- from equipment, sensors, tools

- Industrial IoT technology

- Industrial Big Data technology

- User friendly User Interface

- User friendly reports

- Automatic calculation

- Calculate and setting thousands of specification automatically

- Easily integration with legacy systems

- Easy maintenance and support with adaptation of universal technology

- Production status

- Production performance

- Equipment status, performance, capability

- Process capability

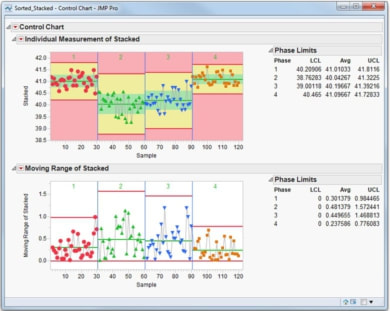

- Multivariate analysis

- Anomaly detection and warning

- Statistical Process Control

- Time series data machine learning with advanced algorithm

- Functions for internal users and customer users

- Virtual metrology

VI-Probe

Bird produces a range of diagnostic systems which are tools for measuring voltage, current and the phase angle between these parameters in complex applications. The VIP System is Bird Technologies' solution to the semiconductor market to provide more information than traditional VI probe instruments. Each system is comprised of a sensor that attaches in-situ in the RF feed line, a receiver that performs the data conversion and communicates to your workstation, and a calibrated data cable that connects the sensor and receiver.

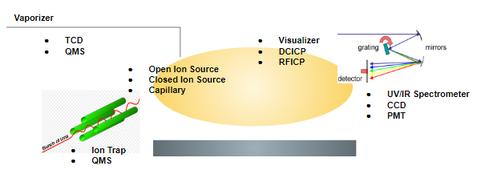

RFICP /DCICP OES Sensor-X

Sensor X provides the highest sensitivity and signal to noise (S/N) performance by breaking up molecular gas species into their discrete atomic components. As such, Sensor X is quickly becoming the industry standard for applications that range from low exposed area oxide etch end point to micro-leak detection to general vacuum chamber troubleshooting.

- UV/Vis Spectrometer

- IR Spectrometer

- PMT

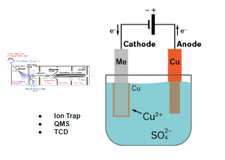

Mass Spectrometer

The 100, 200 and 300 amu residual gas analyzers offer exceptional performance and value. These RGA's provide detailed gas analysis of vacuum systems at about half the price of competitive models. Each RGA system comes complete with a quadrupole probe, electronics control unit (ECU), and a real-time Windows software package that is used for data acquisition and analysis, as well as probe control.

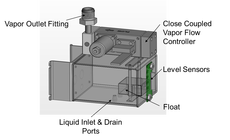

H2 GAS Purity Monitoring

HEMS-M Advantages

1) Resolves ppb and high ppt levels of contamination for H2S

2) Separates different molecular species with the same mass

3) Uses a GC column to separate N2 & CO

4) Measures a wider range of compounds vs. APIMS or optical methods

5) More compact, lower cost, low maintenance, lighter

6) Rugged and simple to operate

7) Capable of moving while powered on (except filament power must be off)

1) Resolves ppb and high ppt levels of contamination for H2S

2) Separates different molecular species with the same mass

3) Uses a GC column to separate N2 & CO

4) Measures a wider range of compounds vs. APIMS or optical methods

5) More compact, lower cost, low maintenance, lighter

6) Rugged and simple to operate

7) Capable of moving while powered on (except filament power must be off)